OUR SERVICES

Solution-Oriented | Quality-Driven

Engineering

Expert knowledge and support.

Viking’s Engineering Team provides design assistance for new parts based on custom requirements for performance. Our goal is to design for economies of scale in manufacturing and source cost-effective raw materials so that you benefit from competitive pricing.

Our Engineers’ knowledge and experience allow for Viking Products to reverse engineer parts and assemblies to help you source quality components faster.

Our expert Engineers provide:

- CAD/3D Imaging (CATIA, UG, Pro-E, Solidworks, IGES, STP)

- Concept to Production CAD Assistance

- Cost-Effective Solutions in Processes and Materials

- Development Assistance

- Engineering & Reverse Engineering

- Finite Element Analysis

- Functional Design Development/”Black Box” Design Assistance

- Linear / Non-Linear

- Mechanical & Design Engineering

- Product Design

- Prototype Development

- Rapid Prototyping

- VA/VE & Design Optimization

Product testing analysis services:

- Full Dimensional Layout Capabilities

- A2LA Certified Testing Laboratories

- Worldwide Testing Leaders Utilized

- Product Testing Validation

- Fatigue Life Testing Capabilities

- DVPR Development

- Customer Tailored Test Reports

Testing

Take your products to market with confidence.

Viking provides comprehensive testing and analysis to ensure your parts meet and exceed all quality expectations.

Quality

Quality is our specialty

Viking is committed to delivering quality products. Our quality lab ensures your part requirements are met by conducting appropriate quality assurance checks, including verification of dimensional specifications, hardness testing (including proof load), and material performance testing.

We stand behind our products and are committed to delivering a seamless experience with quality products and prompt service – every time.

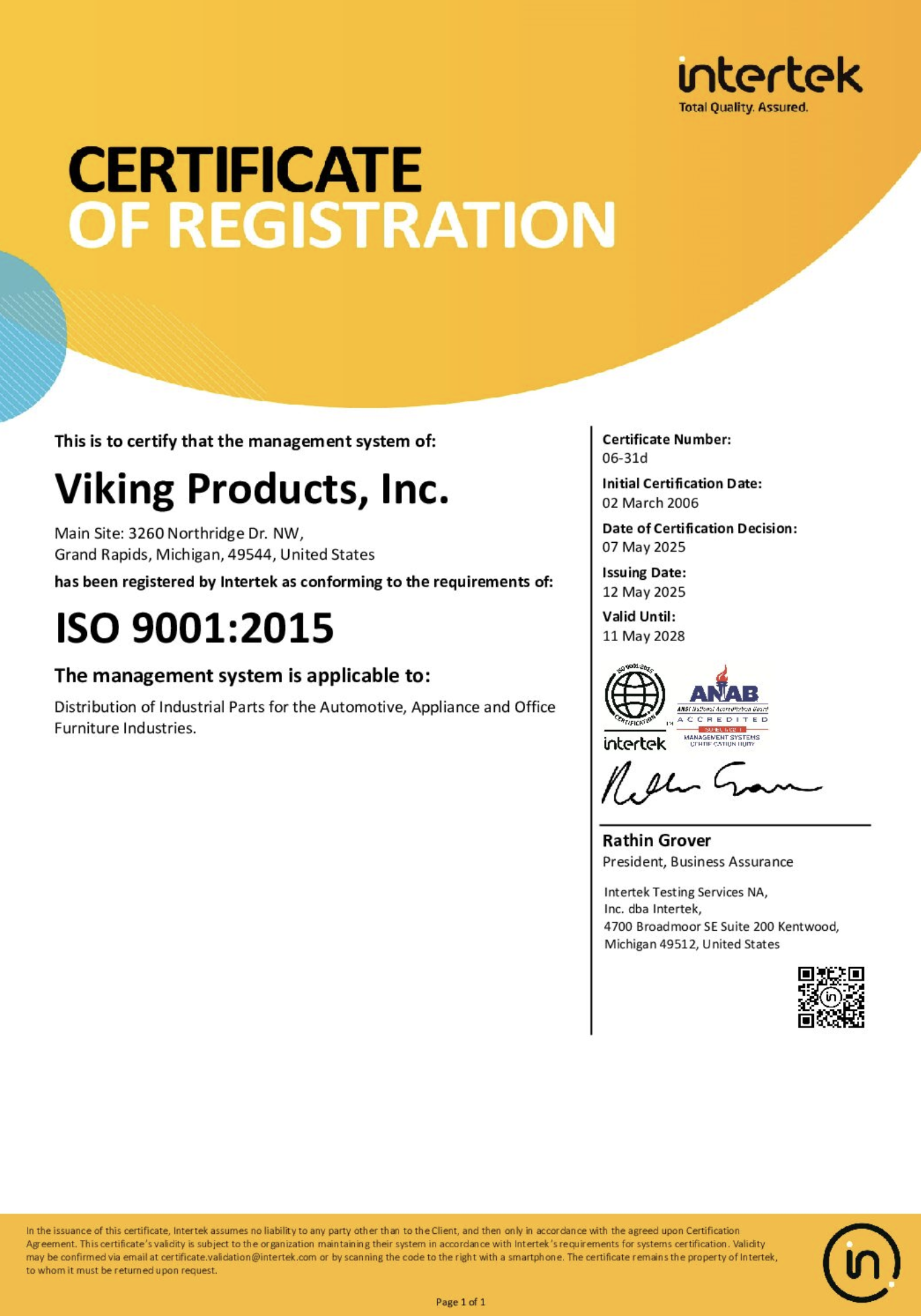

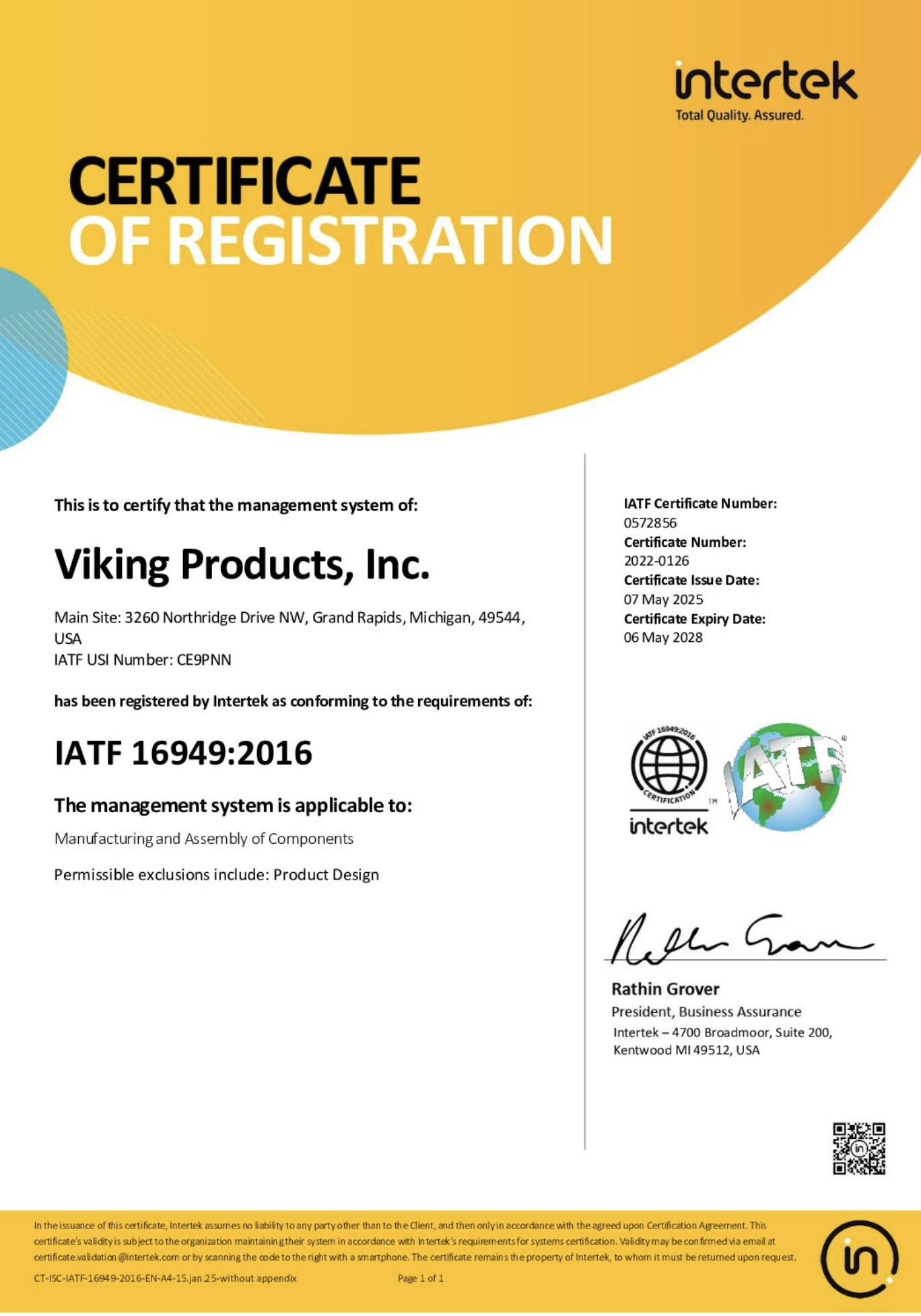

Certified to IATF 16949, ISO 9001:2015, and ISO 14001:2015.